Years of Rich Experiences

We specialize in the R&D and manufacturing of all kinds of steel production line machinery, providing full-process equipment and customized services, with markets covering Southeast Asia, the Middle East and Africa, and seeking global partners.

Experiences

Design and Planning

With 30 years of rich experience in steel rolling metallurgical technology, we can customize the overall solution and planning of steel rolling mill according to customer needs and the design principle of more economical and energy-saving.

Manufacturing and Fabrication

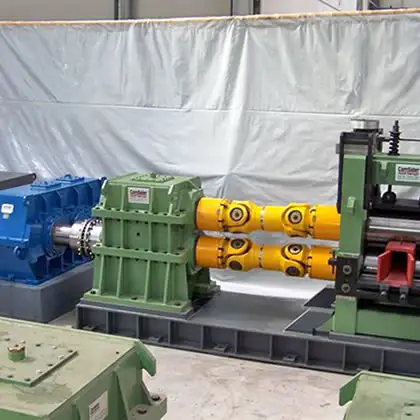

We strictly follow China's national industry standards and quality control system to complete the precision machining of the core components of the rolling mill and the assembly of the entire system, creating rolling mill equipment with stable performance and efficient operation.

Commissioning and Training

We can dispatch a professional technical team to the site to provide installation guidance and optimize the operating parameters through systematic commissioning to ensure that the rolling mill quickly reaches the designed capacity and product accuracy requirements, while also training the customer's own technical team.

Production and Profit

We can recommend professional production teams to help customers quickly achieve stable production, accelerate the return of customer investment funds and enable customers to achieve profits as soon as possible.

Spare parts and Production Line Upgrades

We provide long-term and stable spare parts and technical support. At the same time, according to customers' needs for capacity expansion and product upgrades, we provide rolling mill transformation, increase of multiple types of rolling mill equipment, and production line upgrade solutions to extend equipment life and expand production capacity.

SHENLONG · Machinery · SHENLONG · Machinery

Steel Plant

Through integrated, intelligent and flexible production line design, combined with advanced rolling and controlled cooling technologies, we enable steel mills to produce high-quality steel products that meet the high standards of the market, while reducing production costs and improving competitiveness.

02Iron Mill

We can provide iron mill with a customized solution framework, design and implement the rebar production line that best suits their needs, thereby improving production efficiency, reducing costs, improving product quality, and gaining a competitive advantage in the market.

03Foundry

Rolling equipment solutions tailored for foundries require a professional team to plan, design and implement. Through customized solutions, foundries can achieve transformation and upgrading from "casting" to "casting + rolling" and gain greater market competitive advantages.

Contact us immediately

0086 18595836738

Rolling Mill Maintenance Guide: Maximize Performance, Extend Lifespan, and Reduce Downtime

How to Extend the Service Life of Rolling Mill Rolls: Practical Strategies for Steel, Aluminum, and Metal Rolling Plants

Comprehensive Guide to Rolling Mill Types and Their Production Processes

How to Improve Rolling Mill Production Efficiency: Practical Strategies for Higher Output and Better Quality

With 30 years of professional experience, we customize efficient and energy-saving rolling mill production lines, providing you with one-stop service from design to installation and commissioning, helping you achieve steady growth in the steel industry.

Go

Top

SHENLONG Machinery · Your Rolling Equipment Expert ·